Mobility and Production Coordination

April 7, 2019Carla’s Pasta is one of the largest producers of filled pasta products in America. They have experienced steady growth as their product offerings have increased and sales channels have expanded. But growth in product variety and volume posed new challenges to production. A larger product mix required more frequent product changeovers resulting in a more complex production plan. Executing the plan required better communication and coordination within the factory.

The Challenge: Staying on schedule requires having the right ingredients available for use at the right time. Many ingredients in Carla’s Pasta products require thaw and prep time before they can be used. Ensuring the availability of properly staged ingredients when needed by the Kitchen is critical. With increased product variety and volumes, coordination was becoming more difficult. It became clear that a better method of communication was needed to avoid production delays and scrap due to ingredient unavailability.

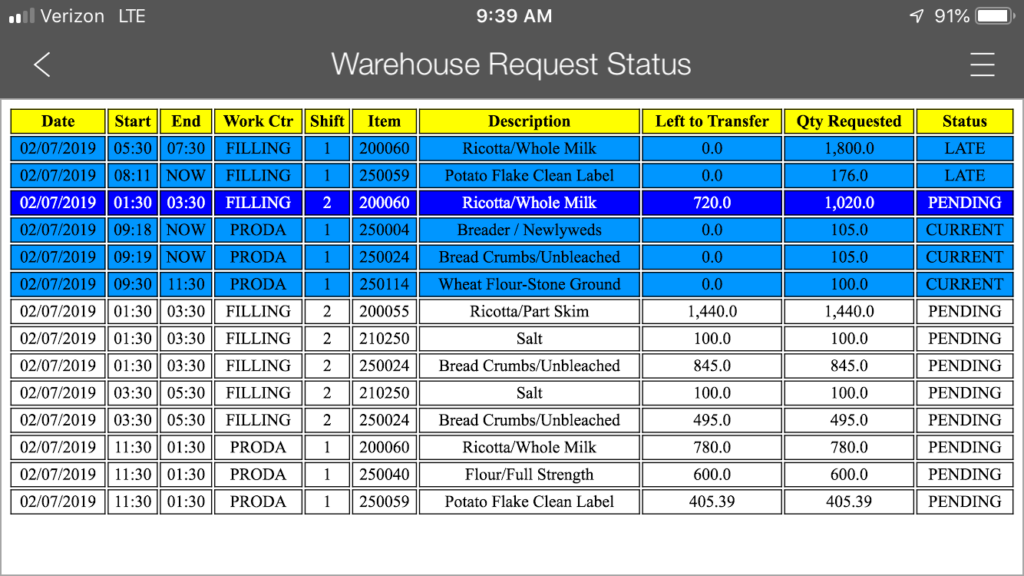

The Solution: An ingredient delivery schedule was created showing how much of each ingredient should be delivered to the Kitchen every two hours. The Kitchen staff enters this daily into the QAD ERP system. As ingredients are received into the Kitchen, they drop off the open delivery schedule. Warehouse personnel can now use the ERP system to check which ingredients remain to be delivered.

Mobility Required: Since warehouse personnel are always on the move and usually without access to the system, it became clear that the delivery schedule needed mobile access. Additionally, a large screen monitor was needed in the Kitchen staging area for workers preparing ingredients to view the same information.

Mobility Delivered: Statusbin was selected because it could easily make reports available on mobile devices. The same reports could also be displayed on a large screen monitor. Additionally, Statusbin was able to transform the delivery schedule into a color-coded report driven by changes happening in the QAD ERP system. Warehouse personnel are now able to check in real time what actions need to be taken to satisfy the delivery schedule.

Benefits Realized: These changes have greatly improved communication between Production and the Warehouse, keeping their activities in sync. As a result, production delays due to ingredient shortages have become a rarity even as the production schedule has grown in complexity.

Return to Blog